Secura Labels Installs All New Proflex 330E Press

Sharon Keevins • September 19, 2017

PRESS RELEASE:

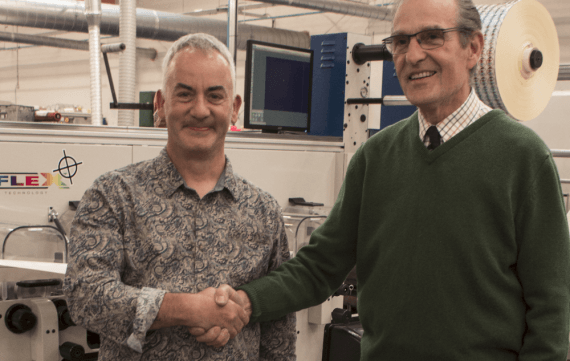

Secura Labels installs all new Proflex 330E press from Focus Label Machinery Ltd.

Specialist label printer Secura Labels Ltd, based in Derbyshire UK, has taken delivery of the very latest 6 colour, full UV Proflex 330E flexo press, manufactured & supplied by UK manufacturer, Focus Label Machinery Ltd.

The new press will be used for production of high quality self adhesive labels and has been purchased to further increase efficiency and productivity.

The Proflex E is a precision lineshaft driven, modular press available with print widths of 250mm and 330mm and a variety of optional drying systems, including full UV, LED, Infra-Red – or combination drying systems, with optional chill rolls for heat sensitive substrates. As standard, the new Proflex E is equipped with touch screen HMI operator interface panels, for all press control functions, plus storage of job information for future reference. The new features are said to reduce set up time and material wastage, resulting in less downtime and higher productivity. The operator can control all aspects of press operation, from any of the HMI touch screen control panels and can store job information for future retrieval on repeat orders. The modular design of the system means that future addition of extra print heads, and other optional equipment, is readily facilitated.

To assist with accurate flexo plate mounting, Secura has also purchased the newly designed Focus Platemate 2 video plate mounting system with twin digital cameras & high resolution colour LED monitor.

Simon Miller, Managing Director of Secura commented “This is our third purchase of a Focus press and will represent a big leap forward for us in terms of productivity and flexibility. Our business has grown rapidly in recent years and we needed to increase our efficiency & capacity. Focus has always provided a reliable back-up service, complemented by quick response times, which were also important factors for us, when considering a new press.”

This investment, the largest in the company’s 35 years history, completes the latest round of spending, following the purchase in 2016 of a Trojan Inkjet Press and a Bar Graphic Machinery Elite, primarily for finishing (cutting) labels finished on the Trojan, but also for use as a Blanks press or rewinder.

Miller says of the investments: “With the backing of the Team here at Measham and that of our Shareholders, the investments have been easy decisions for us to make, and will give us the opportunity to not only offer more options to our existing customer base, but also allow us to attract new markets and customers.”

The press was officially launched by David and Kay Webster, who founded Secura Labels some 35 years ago. David was working for Gerhardt, predominantly on Gerhardt’s Ident Machine agency side, but following redundancy, and after building his own Press, Secura Labels was born; with the first order a multi 1,000,000 label run which saw David and Kay working through the night to complete… the rest, as they say, is history!

Miller reported: “Having David and Kay back to cut the ribbon on the investment was a great pleasure for us, and an opportunity for them to see where the company is now, a very different animal from when they retired some 17 years ago.”

Focus Sales Manager, Antony Cotton added… “Secura Labels has been a good customer of ours for many years, so we are very pleased to continue this successful partnership with the installation of the new Proflex E press.”

If you would like to know what Secura Labels could do for you with their new press then give them a call on 01530 515 170 or email them on sales@securalabels.co.uk now!